Metal working

Company metal production centre fulfils two main principal functions: it´s a source of components used in company´s production processes as well as the producer of components and spare parts for our customers in accordance with obtained drawing documentation.

The own warehouse stock with the wide range of material ensures the short delivery terms for spare parts and examples. Quantity of produced series has no limits, we are mostly oriented on less quantity with highier parts elaborations. Exception are automatic lathes with reverse orientation.

- we accept all formats od drawing docuimentation

- we guarantee fast, accurate and reliable delivery

- check out equipped with modern technologies

- possibility of consequential operations, as surface and heating finishing

- possibility of parts assembling

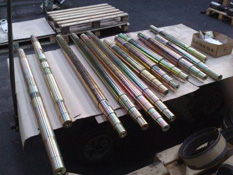

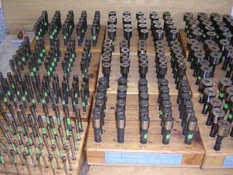

EXAMPLES OF METAL PARTS PRODUCTION

MATERIAL SPLITTING

- metal plate shears splitting

- material CNC saw splitting

- material flame splitting

TOOLING OPERATIONS

- drilling: bench, vertical, radial drilling

- boring: horizontal, vertical, coordinate boring

- turning works: multi-spindle automatic lathe turning

- turning operations

- CNC turning

- milling works: horizontal boring machines, tooth system milling machines, milling machines

- grinding works: opening grinding

- point grinding

- flat grinding

- tools grinding

- round grinding

- planing: planning operations

- slotting operations

- machining centres: CNC machining, CNC milling

- spark-out operations: electroerosion cutting

MATERIAL HEAT TREATMENT

- annealing

- nitration

- hardening

- cementation

- tempering

MATERIAL WELDING

- arc welding

- gas welding

- point welding, gas-shielded welding

- metal construction welding

TOOL-MAKING OPERATIONS

- metal mould production

- design and tool-making works